Recyclable Packaging Solution FrameTray™

FrameTrayTM is an environmentally friendly and cost-effective packaging provided by Boxon. It is a type of optimized injection-molded packaging that can be designed specifically for each product, and, most importantly, is recyclable and can be reused for making new FrameTrayTM. It is widely used in the automotive industry for parts such as crankshafts, pistons, camshafts, flywheels, and EV batteries that requires testing with dangerous packaging.

Boxon has provided FrameTrayTM for over 10 years to various automotive brands in their global supply chains. We have set up the recycling centers for FrameTrayTM in Europe and Asia and have the operational experience essential for safe and timely transportation of customers’ goods.

Advantages of FrameTray™

There are many advantages of FrameTrayTM.

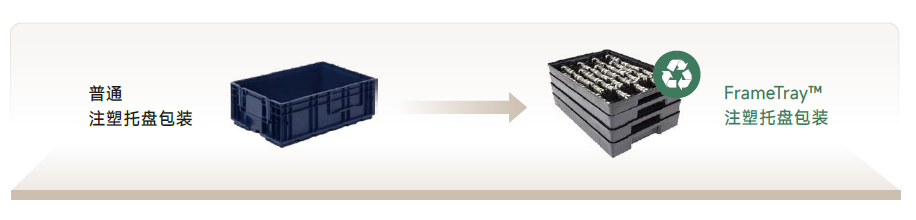

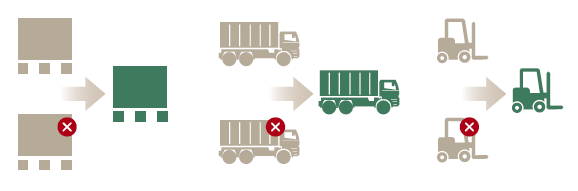

Firstly, injection-molded plastics technology enables standard boxes traditionally combined with various types of inserts to be replaced with lean packaging. Boxon’s FrameTrays have been shown to achieve up to 50% greater packing capacity when used in various application areas. It also simplifies the handling when packing goods. Thus, it saves the cost of transportation and labor.

Secondly, FrameTrayTM develops a closed loop of material recovery, ensuring 100% plastic reuse throughout the entire supply chain. Therefore, it can significantly reduce CO2 emissions and contribute to sustainability goals.

Thirdly, FrameTrayTM can save the supply chain cost for customers due to our operational centers in Europe and Asia.

Last but not least, FrameTrayTM is produced in a clean environment so they do not contaminate customers’ products.

All in all, FrameTrayTM is a cost-effective and environmentally friendly solution.

The Closed Material Loop

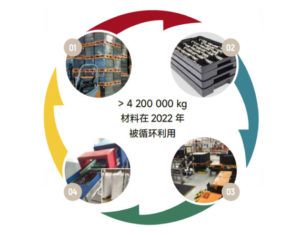

FrameTrayTM develops a closed material loop from manufacture, use, recycling and re-manufacture.

- FrameTray™ Manufacture

We produce customized trays to meet customers’ ongoing demand.

- Automotive sub-supplier

The tire 1 suppliers loads the trays with automotive spare parts and sends them to the OEM unit with an average 40-50% better pack density.

- Vehicle & Engine Plants OEM

The goods are used in the automotive assembling line and the empty packaging is sent to the local tray recycling center.

- FrameTrayTM Recycling Hubs

Trays are shredded down to plastic chips close to plants and transported back to the FrameTrayTM production facility for reuse with 90% better volume utilization.

4200 Tons in a Closed Loop

There has been a rapid growth in the automotive industry for the demand for FrameTrayTM in recent years. In 2022, Boxon reused approximately 4200 tons of plastic material in total into new FrameTrayTM.

“We have a very exciting journey ahead of us with increasing demand for FrameTrayTM from our global customers. The uniqueness of this solution is that we support our customers to reuse all packaging materials in a closed loop, at the same time reducing transportation costs significantly. Of course, this also reduces CO₂ emissions, both due to efficient transport utilization and the reuse of material,” said Tobias Rasmusson, General Manager at Boxon Tech AB.

Share

Related Posts

Leave a Reply